Vision Systems Engineers

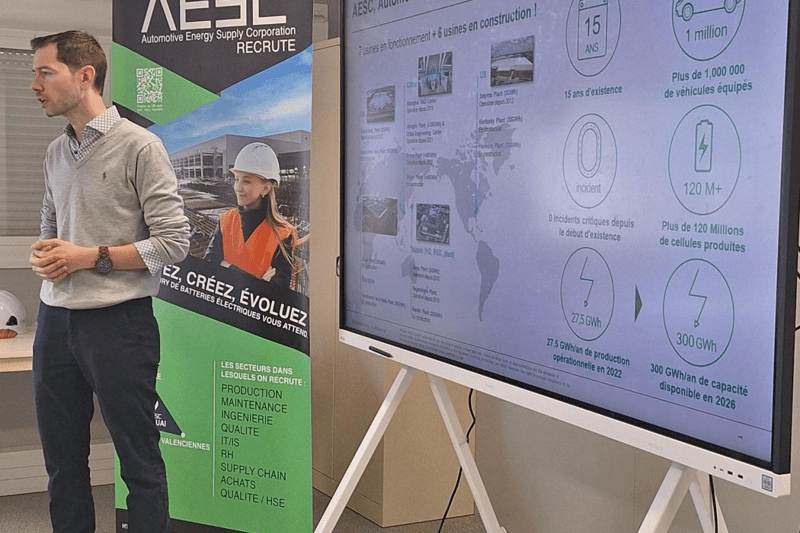

About AESC

AESC Group, founded 2007, is a global leader in the development and manufacturing of high-performance batteries for electric vehicles (EVs) and battery energy storage systems (BESSs), with R&D centres and over 13 manufacturing bases in Japan, China, Europe and the US. AESC’s commitment to excellence ensures the delivery of high-performance, cost-effective, and safe products and achieved a record of “zero critical battery malfunction”. AESC invests heavily in next-generation technology to drive innovation and works with its strategic partners to continually push the boundaries of performance, safety and efficiency.

Our profile

We are setting up the Global Engineering Centre (GEC) Europe as part of the global GEC, working closely with entities in the US, China and Japan. As part of GEC Europe, you will be part of a diverse team of individuals who are highly skilled in battery cell manufacturing and have a proven track record in designing and ramping up battery cell manufacturing facilities worldwide. Together we will build the future of battery manufacturing in Europe.

The role

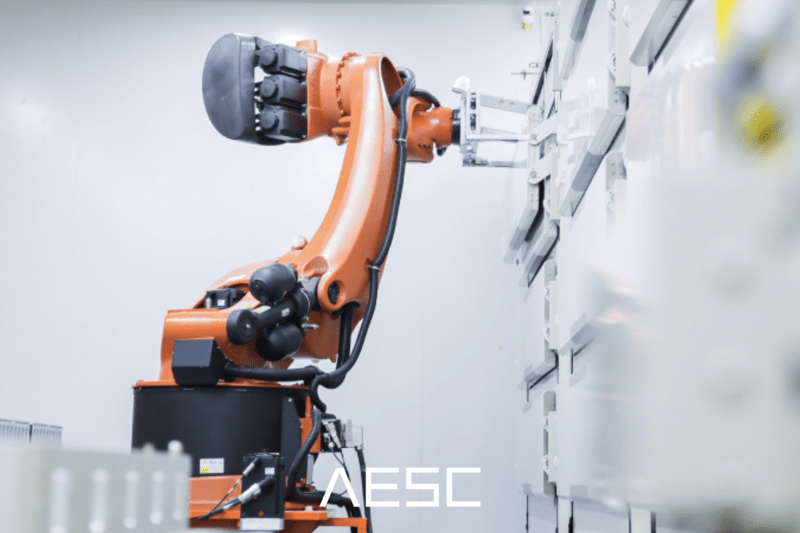

As a vision systems engineer, your objective is to lead the development and optimization of industrial vision systems for battery cell production. You will work with machinery builders and integrators in the commissioning and setup of vision systems on the shop floor. Through close collaboration with equipment and process engineers, production teams, automation and our global engineering network, you will contribute to the successful scaling of our battery manufacturing operations in Europe.

Responsibilities

• Develop, implement and optimize industrial vision systems for battery cell production

• Lead and support vision systems topics during commissioning and ramp up, working with external and internal stakeholders.

• Be able to troubleshoot and optimize vision system applications, working with algorithms, parameters, detection areas, focus, lighting, brightness, quality, cycle time, contrast, image storage, false positives, false negatives, communication protocols and data payloads.

• Design and conduct DOEs on vision systems designed for mass production.

• Capture learned lessons and share best practices to other AESC sites within the EU and Globally.

• Provide vision systems expertise and support to changing requirements and issues. Working to improve key KPIs related to detection process steps. (OEE, Scrap rate and quality).

• Support with specification writing and selection of vision systems utilized in future projects.

Qualifications:

• Bachelor’s Degree in related field.

• 5+ years of experience in Vision and detection systems.

• In-depth experience with common industrial vision system vendors: Cognex, Keyence, Omron, Basler, Teledyne and SICK.

• Experience in C++, Python or Matlab.

• Knowledge of image data storage.

• Experience of detection of flaws, dents, defective sections and scratches on the product’s surface.

• Experience in range of cameras, lightning systems, lenses and sensors.

• Experience in light level, background color level and motion appropriate to fault detection.

• Familiar with in-depth analysis of detection systems failures for high-speed manufacturing rates.

• Knowledge of the main image processing algorithms and their use cases.

• Leadership in problem-solving / root cause analysis efforts for complex detection issues.

• Experience of creating and conducting data analysis for image processing.

- Departments

- Engineering

- Locations

- Douai, France

Work at a world-class and innovative Gigafactory

AESC is investing almost two billion euros to build a battery manufacturing plant in the Hauts-de-France Region. The new Douai site will have a production capacity of 9GWh in 2024, with the potential to reach 24GWh by 2030 to produce state-of-the-art, low-carbon batteries. The site will initially supply the Renault factory which will be increasingly dedicated to producing the brand’s electric vehicles.

What can AESC offer you?

-

Learning and development

AESC is a company that invests in its employees by offering a wide variety of training and development programs. Engineering training and onboarding programs for all business-critical-related functions. As the French entity is new, AESC is also investing in developing full employee onboarding plans. International development and learning possibilities for all employees in a worldwide environment.

-

Culture and Colleagues

AESC is an international company with production entities in Japan, the US, the UK, and China. A strong multi-cultural management team and organization; with a strong respect and a good understanding of cross-culture differences. Offers the platform for unlimited worldwide development opportunities for the employees to grow their careers.

-

Work in an innovative, world-class Gigafactory

AESC is investing nearly €2 billion to build a battery manufacturing plant in the Hauts-de-France region. The new Douai site will have a production capacity of 9 GWh in 2024, with the potential to reach 24 GWh by 2030 to produce state-of-the-art, low-carbon batteries. The site will initially supply the Renault plant, which will increasingly be dedicated to the production of the brand's electric vehicles.