AESC | Contamination Engineer

This position is no longer active

Either the position was filled, or the ad has expired.

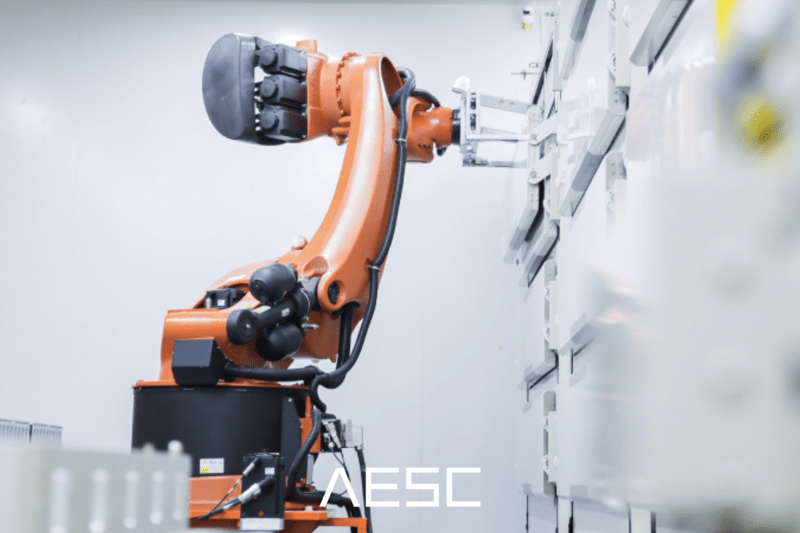

Work at a world-class and innovative Gigafactory

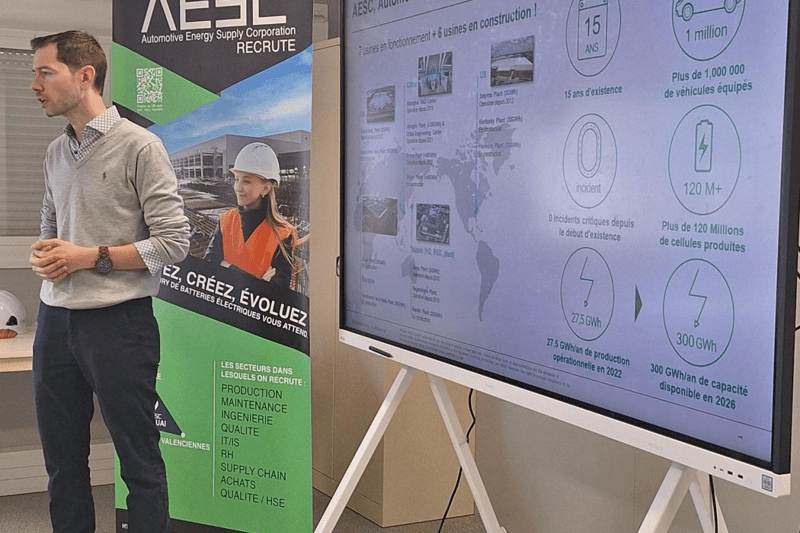

AESC is investing almost two billion euros to build a battery manufacturing plant in the Hauts-de-France Region. The new Douai site will have a production capacity of 9GWh in 2024, with the potential to reach 24GWh by 2030 to produce state-of-the-art, low-carbon batteries. The site will initially supply the Renault factory which will be increasingly dedicated to producing the brand’s electric vehicles.

What can AESC offer you?

-

Learning and development

AESC is a company that invests in its employees by offering a wide variety of training and development programs. Engineering training and onboarding programs for all business-critical-related functions. As the French entity is new, AESC is also investing in developing full employee onboarding plans. International development and learning possibilities for all employees in a worldwide environment.

-

Culture and Colleagues

AESC is an international company with production entities in Japan, the US, the UK, and China. A strong multi-cultural management team and organization; with a strong respect and a good understanding of cross-culture differences. Offers the platform for unlimited worldwide development opportunities for the employees to grow their careers.

-

Work in an innovative, world-class Gigafactory

AESC is investing nearly €2 billion to build a battery manufacturing plant in the Hauts-de-France region. The new Douai site will have a production capacity of 9 GWh in 2024, with the potential to reach 24 GWh by 2030 to produce state-of-the-art, low-carbon batteries. The site will initially supply the Renault plant, which will increasingly be dedicated to the production of the brand's electric vehicles.